A palletizer is a device that automatically sorts, moves, and stacks cases of goods or products onto a pallet. These machines are often found at the end of a production line. Palletizers offer load stability, accuracy, and speed of operation. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

TopTier is the leader in innovation and value -- providing palletizing solutions with speed, flexibility, and dependability for 24/7 operations. Founded in 2003, TopTier installs floor and upper level infeed single automatic palletizers or systems integrated with existing conveyor and other material handling equipment. Both row-forming and robotic technologies from TopTier make palletizing...

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

DePeuter Packaging Solutions (DPPS) is a provider of end of line packaging equipment, including palletizers, depalletizers, single cell robotics, case packaging machines, conveyor systems, and totally integrated factory automation systems. From small single cell projects to complete turnkey systems, our team of experienced engineers and technicians will be available to assist with any application.

Our powerful magnetic palletizer and depalletizer can lift and position layers of steel cans at one time from a multi-layer stack, and can do it quickly without tumbling, jamming or can damage. Our palletizer/depalletizer magnets can be built in various sizes to fit the can stack configurations of your workplace. Choose Eriez for solutions to your palletizing needs.

More Automatic Palletizer Manufacturers

The machine itself might handle more control and work. The range of goods that palletizers could handle expanded and now include things like bottles that would be challenging and expensive to palletize by hand. Automated palletizing systems are widely used in manufacturing and distribution facilities because they can handle heavy loads and repetitive motion much better than manual laborers. They are especially helpful when handling individually-packaged products, which can be physically demanding, awkward, and dangerously heavy when handled by hand.

Materials Used

The pallet is typically rectangular and has a standard size of 40 inches by 48 inches. It may be wood, plastic, metal, or corrugated Kraft board.

Types of Automatic Palletizers

- Robotic Palletizers: available as automatic or semi-automatic, they generally occupy the space between a pallet dispenser and a belt line carrying incoming goods. The product is lifted by a hydraulic robotic arm and carefully placed onto a pallet. Robotic palletizers can only lift one item at once but can stack items considerably quicker and reduce the risk of workers being hurt or becoming fatigued.

- Conveyorized Palletizers: feature a feed area where the items to be palletized are placed. They move quicker than robotic palletizers as packed units are continually moved and sorted by automated conveyor rollers. Conveyorized palletizers come in two varieties: low-level and high-level.

- Low-Level Palletizers: Products are frequently placed immediately in the packaging area, downstream from the case packing machinery, where low-level machines take the product from the floor level and prepare it for palletizing.

- High-Level Palletizers: These palletizers may accept goods already at ceiling level or raise them to the appropriate height using an incline or spiral conveyor.

Construction of Automatic Palletizers

- Hydraulic, pneumatic, or electromechanical machinery may power automatic palletizers.

- Bag, case, drum, and bottle palletizers are a few examples of automated wrapping machinery that can be designed to handle a certain product. They may also be built to handle various items.

- To help manage pallets and loads, automatic-palletizing equipment accessories like pallet dispensers and load transfer stations are also employed.

Working of Automatic Palletizers

- A hydraulic robotic arm stacks units with almost perfect accuracy by lifting cases, bottles, bags, or drums with flat pincer arms or suction cup arms in orderly rows onto a pallet.

- Although they may be slower since they can only place one unit or row at a time, robotic palletizers may be modified to deal with many product units and are good for handling fragile or heavy ones.

- The majority of the mechanical components in conventional versions still come from a computer.

- When the bags come on conveyor belts, they are stacked from the top after the pallets are loaded into the machine from the bottom.

- Items are positioned or rotated by pre-determined arrangements. Then, they are pressed together to form a row.

- With high-level palletizers, a layer of items is formed on a plate, then raised above the pallet before being pulled down, allowing the layer to fall onto the pallet.

Benefits of Automatic Palletizers

- Superior uptime and high system dependability boost total throughput.

- Managing heavy lifting and repeated actions enhance ergonomic conditions and lower operational expenses.

- As a firm grows, seamless integration is adaptable and scalable.

- Connection points to downstream and upstream machinery are accessible for fully automated operations

- Using unique pallet-pattern software improves pallet-load density, stability, and accuracy.

- They provide accurate and secure handling of various products, including buckets, bins, batteries, irregularly-shaped or heavy objects, trays, cases, totes, bags, and tier sheets.

Applications of Automatic Palletizers

- Shipping, packing, distribution, and other materials-handling activities are typical uses for automatic palletizers.

- Automatic palletizers are used in various sectors, including electronics, food processing, agriculture, warehousing, retail, and pharmaceuticals.

- These automatic palletizers are best used in applications where packing and shipping speed is important.

- Recently, robotic palletizing systems for food packaging have been reported.

- Applications for palletizing and depalletizing remain a bright light for the robotics sector.

Choosing the Proper Automatic Palletizer Manufacturer

To ensure you have the most positive outcome when purchasing an automatic palletizer from an automatic palletizer manufacturer, it is important to compare several companies using our directory of automatic palletizer manufacturers. Each automatic palletizer manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each automatic palletizer business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple automatic palletizer companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

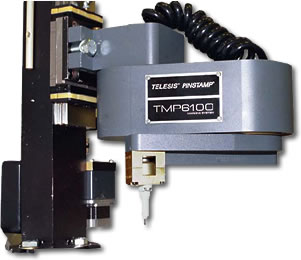

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches