Pallet dispensers may separate and distribute one pallet or slip sheet at a time. The dispenser has a chamber to hold a stack of empty pallets or slip sheets, an exit conveyor, electric, pneumatic, or hydraulic lifting actuators, prongs to engage the stack, and lifting actuators. There are many different sizes and forms of pallets. The most common pallets are “two-way” or “four-way” pallets. As a result, there are two basic dispenser designs, a two-way and a four-way pallet dispenser based on the differing fork and lifting operations these pallets need. Most dispenser types and sizes are chosen based on the application’s needs. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

DePeuter Packaging Solutions (DPPS) is a provider of end of line packaging equipment, including palletizers, depalletizers, single cell robotics, case packaging machines, conveyor systems, and totally integrated factory automation systems. From small single cell projects to complete turnkey systems, our team of experienced engineers and technicians will be available to assist with any application.

More Pallet Dispenser Manufacturers

A stack of pallets is placed into the chamber using a forklift or an in-feed conveyor for pallet dispensers, customarily made to accommodate single-size pallets or slip sheets. The stack is raised off the bottom pallet by the forks, which have engaged the second pallet. The stack is lowered onto the conveyor when the bottom pallet leaves on an exit conveyor. Slip sheets are distributed the same way, and the operation is repeated until the dispenser is empty.

Features of Pallet Dispensers

- These heavy-duty structures feature a welded construction that can resist wear and tear from industrial use.

- They work independently. The dispenser can operate on its own without being included in an automated system.

- In the pellet hopper, the gravity flaps ensure that top-loaded pallets stack steadily and squarely.

- Automated systems provide adjustable pallet-ejection interval settings.

- Some dispensers allow loading in three directions. Loading can occur in any direction (left-handed, right-handed, or inline) except the direction of dispensing.

- They have low-level detection, which allows the dispenser to warn users when there are insufficient pallets.

Types of Pallet Dispensers

- Auto-Load Dispensers: When production depends on timely and accurate palletizing, auto-load dispensers are excellent for multiple pallets. Such types provide continuous operation and are ideal for handling larger-sized cargoes. Up to three stacks of 10–12 items can be stored in auto-loading settings. These machines allow for either side or inline loading.

- Enhanced-Pallet Dispensers: With this type, pallets are removed from the pile by pulling the stack up while leaving the bottom pallet in place. The stack is reassembled once the isolated pallet has been taken out. Enhanced pallet systems can feature side or inline loading and can hold 12 to 15 items.

- Standard Pallet Dispensers: The pallet at the bottom of the stack is removed using a sweeping chain in a standard pallet dispenser. These solutions are perfect for projects needing top caps, slip sheets, and layer sheets. Standard setups offer side loading and have a 12 to 15 component capacity.

Material and Construction of Pallet Dispensers

- Some pallet dispensers are made with a welded, steel-tubing structure. NEMA 4 enclosures feature an enamel surface that has been abrasion-blasted.

- Pallet dispensers often have heavy-duty construction, excellent reliability, and the capacity to link with current machinery.

- These machines include a strong, steel frame and a powerful scissor lift to move the pallets up and down.

Working of Pallet Dispensers

- A pallet dispenser distributes pallets one-by-one into the conveyor or the work area from a storage capacity of several pallets, often between 15 and 20 pallets.

- Pallet dispensers come in manual and automated varieties.

- Manual pallet dispensers are unloaded using a forklift.

- Pallets may be accessed by a forklift or a hand pallet truck from the front or the sides, with the forklift accessing one side and the hand pallet truck emptying from the other.

- Automatic pallet dispensers utilize their power to dispense the pallet rather than requiring it to be loaded by another piece of machinery. They can be driven by hydraulic, pneumatic, or electromechanical methods.

Benefits of Pallet Dispensers

- They reduce manual work and ergonomic problems.

- They increase production by reducing cycle time and cut costs by extending pallet life.

- They feature completely-welded, heavy-duty construction.

- Standard models contain a hydraulic lift table; advanced models may have an optional electromechanical lift.

- Pallet fingers work pneumatically to dispense.

- Options for an independent control package are available.

- They are easily incorporated into fully-automated systems for pallet handling and packing.

Applications of Pallet Dispensers

- Pallets can be placed accurately into conveyors or dropped directly to the ground using pallet dispensers.

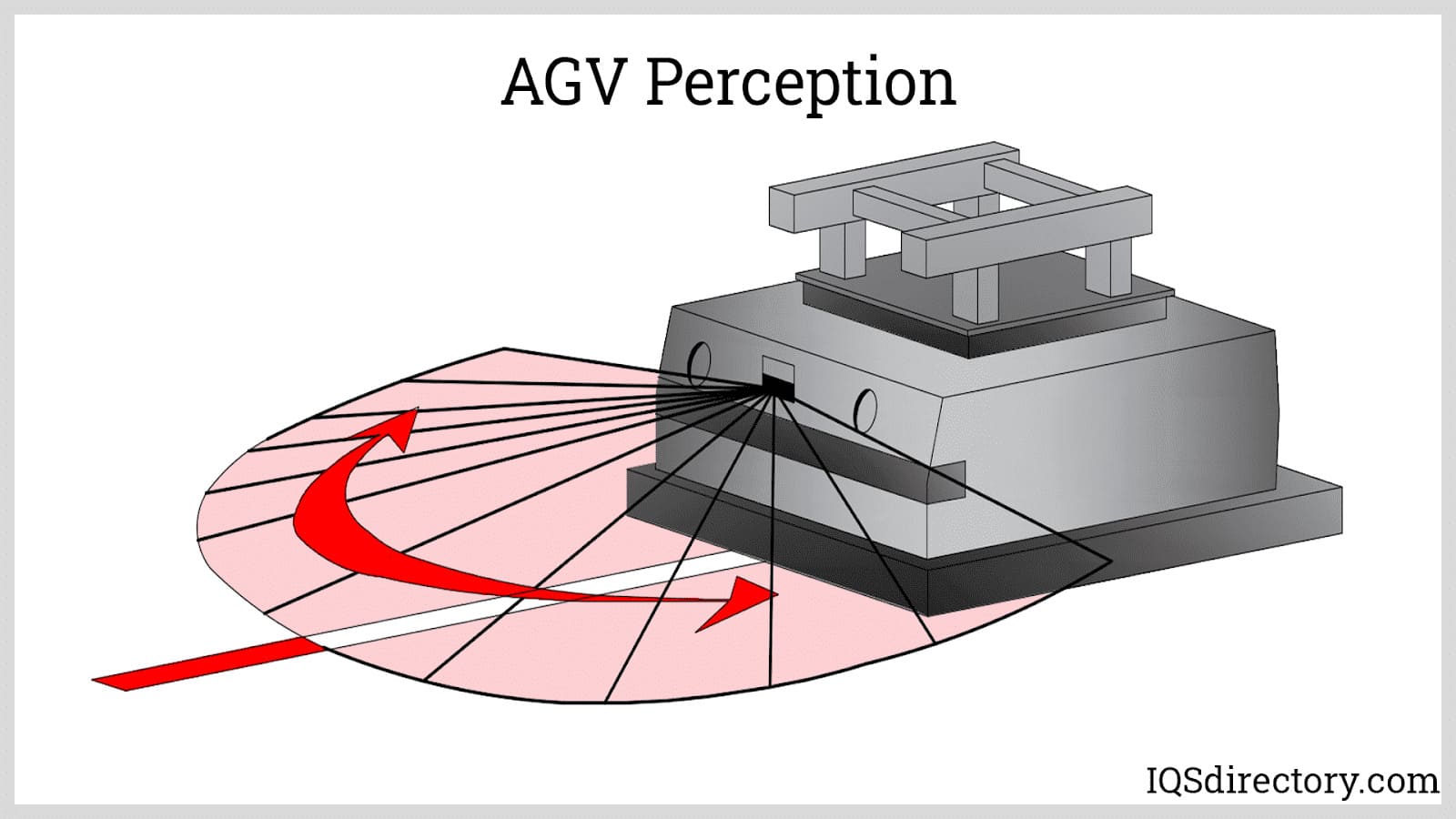

- High-speed automated palletizing, load-forming lines, manual access for pallet dispensing and storage, ASRS systems, pallet-repair systems, and AGV systems are typical applications for pallet dispensers.

- Pallet dispensers are helpful in the medical, cosmetics, consumer goods, food processing, warehousing, chemical processing, material handling, paper, and pharmaceutical sectors.

- Another beneficial application is to combine a pallet recycler and dispenser into one empty-pallet, auto-washing system.

Choosing the Correct Pallet Dispenser Supplier

To ensure you have the most productive outcome when purchasing a pallet dispenser from a pallet dispenser supplier, it is important to compare several companies using our directory of pallet dispenser suppliers. Each pallet dispenser supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each pallet dispenser business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple pallet dispenser companies with the same form.

Pallet Dispensers Informational Video

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches