Pallet inverters allow pallets to be transferred, stacked in a warehouse, or moved to a shipping container, often independently. They are managed hydraulically by a driver of a vehicle resembling a forklift. Pallet inverters reduce the need to manually stack or transfer merchandise from one pallet to another. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

DePeuter Packaging Solutions (DPPS) is a provider of end of line packaging equipment, including palletizers, depalletizers, single cell robotics, case packaging machines, conveyor systems, and totally integrated factory automation systems. From small single cell projects to complete turnkey systems, our team of experienced engineers and technicians will be available to assist with any application.

More Pallet Inverter Manufacturers

Many businesses widely used pallet inverters since they are secure and boost output. Pallet movement or transfer involving physical labor would dramatically raise the risk of injury and product damage. In earlier pallet designs, a loaded pallet is turned by a machine. Newer, more technologically-advanced pallet inverters have remote controllers, and changers integrated into their production processes. Customized pallet inverters may be transported throughout a warehouse or manufacturing facility. Some fully-automated ones can load products onto a fresh pallet at one end of a conveyor line and deposit them at the opposite end.

Types of Pallet Inverters

- Manual pallet inverters: These are most commonly used in small facilities and are typically operated manually.

- Electric pallet inverters: Typically seen in massive warehouses, these devices are powered by electricity. They may be used to turn several pallets at once and provide a higher level of automation.

- Pneumatic pallet inverters: These tools depend on air pressure and are frequently utilized in giant warehouses. They may be used to turn several pallets at once and provide a high level of automation.

Items Used by Pallet Inverters

- Aluminum or plastic, in locations where cleanliness is a concern

- Products typically utilizing internal pallet racking

- Pallets with unique dimensions or designs to suit a particular sector's needs

- Wooden pallets, especially if aluminum or plastic were utilized in manufacturing

- Slip sheet or other lightweight pallets that save on shipping weight and pallet expenses

- Spacers for freezers or sling bags

Working of Pallet Inverters

- The cargo is put or fed onto the conveyor that feeds the pallet inverter.

- The load is delivered into the inverter by a feed conveyor activated by push-button control. When a roller sensor senses a load on the machine, the integrated conveyors start operating automatically.

- The built-in conveyors stop working after directing the bag into the inverter. The hydraulically-driven clamping mechanism applies a suitable amount of pressure to secure the load inside the unit properly.

- The device rotates the secured load until it reaches 180 degrees. The bag leaves the inverter through the built-in conveyor while the clamping mechanism automatically opens.

Benefits of Pallet Inverters

- The pallet inverter allows you to move significant volumes simultaneously, instead of only one box at a time.

- Additionally, they provide adaptability by allowing you to quickly convert between different pallets without buying new equipment.

- The inverter also functions as a load straightener since it can often square loads that are improperly stacked or inclined in order to make them safer.

- Pallet inverters can be adapted to reliably perform highly-specialized functions.

- Pallet inverters are more effective at moving, storing, and stacking pallets than forklifts and provide more stacking possibilities, create less hassle, and are much less likely to damage to contents than forklifts.

- Pallet inverters are also perfect for processes where frequent rotation of more significant volumes is necessary during or after manufacturing. The machine can spin numerous amounts concurrently rather than just a single box.

- Pallet inverters provide easier access to the bottom of loads versus having to manually unload stacks of products off pallets.

- They provide a quick method of flipping over products so their contents don’t settle.

- Pallet inverters can function as standalone equipment, or be built directly into production lines.

- Pallet inverters also allow for quicker transport of frozen items by providing easy access to the freezer spacers between boxes.

Applications of Pallet Inverters

- Loads up to 4,400 pounds may typically be handled by pallet inverters. They may be found in pharmaceutical and food processing facilities where goods are taken off pallets and put in more sterile settings to meet hygienic requirements.

- Pallet inverters are also used to shift goods from internal pallets to less costly pallets for transportation.

- Additionally, they may be utilized to quickly and efficiently remove undesired items off pallets and straighten loads that may have slipped out of a stack.

- Pallet inverters are also widely utilized in other sectors of the economy, such as the chemical sector, where they are employed to prevent contamination from potential leaks of other palletized cargoes.

- Pallet inverters provide more uniform pallets which help make warehousing and manufacturing more efficient.

Choosing the Correct Pallet Inverter Supplier

To ensure you have the most productive outcome when purchasing a pallet inverter from a pallet inverter supplier, it is important to compare several companies using our directory of pallet inverter suppliers. Each pallet inverter supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each pallet inverter business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple pallet inverter companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

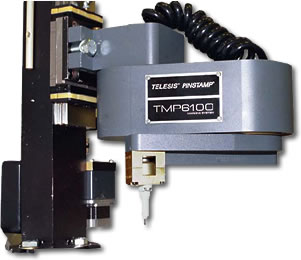

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

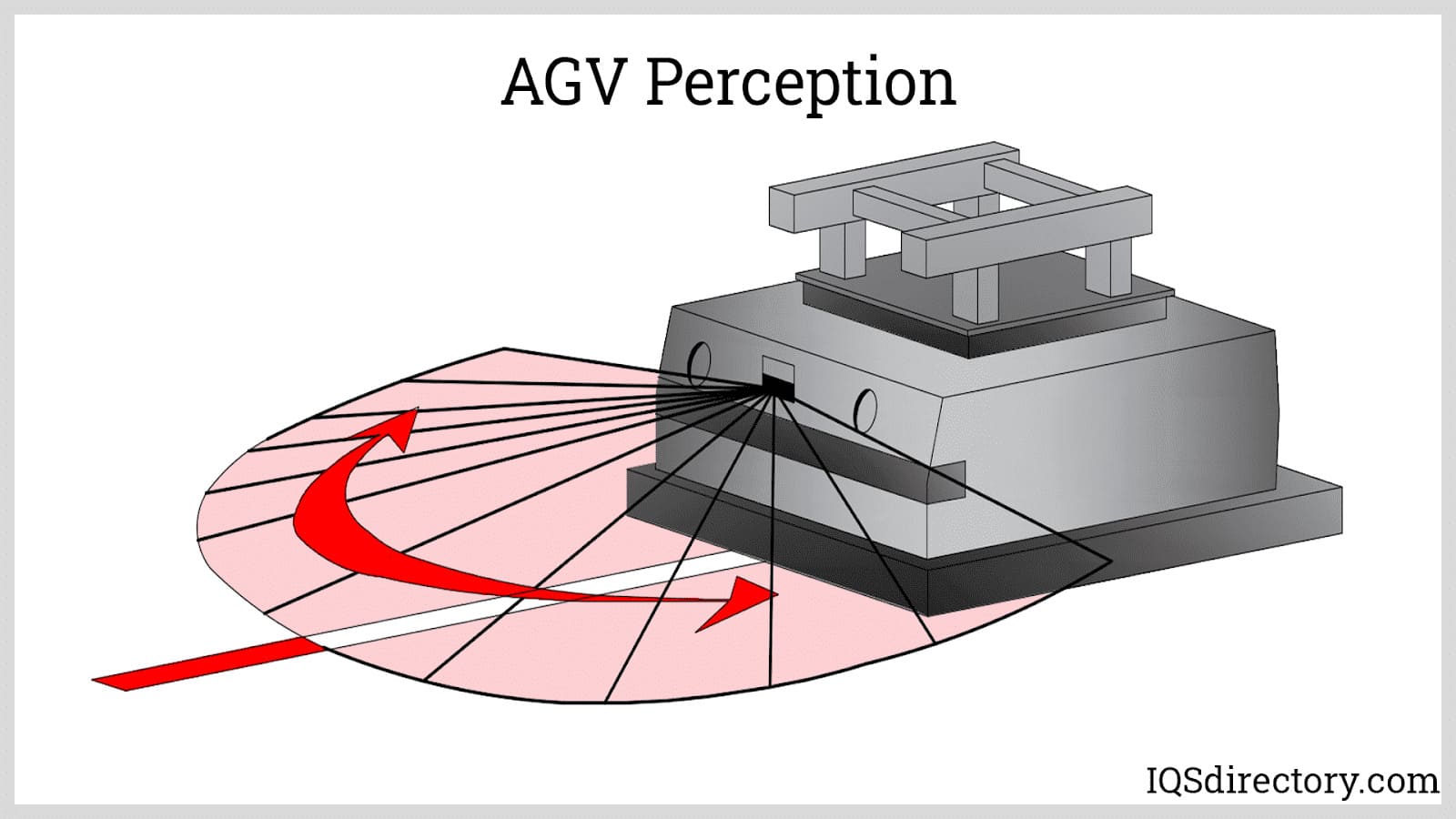

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches