The process of loading products onto a pallet using an industrial robot is called robotic palletizing, and industrial robots used specifically for this purpose are known as robotic palletizers. Depending on the pallet layout, a robotic palletizer can work with one or more units at once and can build many layers on the pallet after selecting the products of the conveyor.Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more.

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems.

DePeuter Packaging Solutions (DPPS) is a provider of end of line packaging equipment, including palletizers, depalletizers, single cell robotics, case packaging machines, conveyor systems, and totally integrated factory automation systems. From small single cell projects to complete turnkey systems, our team of experienced engineers and technicians will be available to assist with any application.

More Robotic Palletizer Manufacturers

Many robots can be used for palletizing. Since the pallets are made with different designs, specialized palletizing robots are used to move heavy, oversized items quickly. When the robotic palletizer is programmed well, it can work with pallets of items of various sizes and forms, separating or mixing them according to the nature of the work at hand.

The other advantage of using a robot in palletizing is that a robot is simple to train for completely new product lines, unlike traditional palletizing robots that would take months of mechanical design. In addition, the robotic palletizing system has high efficiency, accuracy, and reliability. At the same time, using robotics palletizers reduces the rising labor costs and industrial accidents, providing a safe working environment and maintaining working operations. The robot can pick and position different SKUs on various pallets using information sent by vision systems.

How Robotic Palletizers Work

The key element of a robotic palletizer is a robot that can function independently while receiving commands from a programmable logic controller. The computer program determines the distance from the robot's center to the reach of the furthest extension of the arm. When palletizing products from a low to a high elevation, it is vital to consider that this frequently has a spherical shape.

The criteria for the robot's operation now include the palletizer's payload, which considers the weight of the end-of-arm tool and the goods it is handling. This overall payload will be reduced if the end-of-arm tool or product has any offsets. Consideration should also be given to speed. A simulation is frequently needed to verify the necessary speeds.

In most palletizing applications, products are placed so that they are parallel to the floor, so a 4-axis robot is typically employed. However, robots with five or six axes can be used when products need to be rotated or slanted.

Another crucial component is the gripper (end-of-arm tool), which is constantly altered to handle objects and give the robot a ton of adaptability. Depending on the pallet layout, a robotic palletizer can handle one or more units simultaneously and generates various levels after picking the products off a conveyor. A robotic palletizer begins by identifying the type of load that needs to be palletized, picking it up, and placing it on a pallet alongside other loads of the same type.

Many palletizers are present today on the market, depending on the product. Various robotic palletizers employ various end-of-arm equipment, such as a vacuum, clamp, and fork. The brain of any robot system is the end-of-arm tool.

Clamp arms hold onto the sides of the products; they have the ability to carry more than one product with the same orientation.

Types of Robots Used In Palletizing

- Palletizing Robots – These are substantial robots with a long reach and a large payload capacity. Axis connection is a common design choice that enables the robot's elbow actuators to be locked into its base, enhancing speed and payload capacity.

- Six-axis Industrial Robots – These are useful for many activities around the workspace, including palletizing, thanks to their versatility.

- Delta Robots – Delta robots can be used for intricate palletizing activities and are often used for high-speed pick and place operations.

- Collaborative Robots – Most suitable for slow-moving, low-payload assignments.

Applications of Robotic Palletizers

- Reduces labor and inefficiency-related costs

- Reduces noise, lifts heavy burdens, and reduces repetitive movement to enhance safety

- Responds to changes in the production line, whereas conventional palletizers must be notified

- Flexible enough to handle a variety of sizes, shapes, and weights for one or more lines

- Low maintenance requirements

- Saves time when loading or unloading products

- Accurate—no room for shipping the wrong products

Disadvantages of Robotic Palletizers

- Requires a lot of maintenance since there are many moving parts

- Malfunctions can lead to product damage

Choosing the Correct Robotic Palletizer Manufacturer

To ensure you have the most constructive outcome when purchasing a robotic palletizer from a robotic palletizer manufacturer, it is important to compare several companies using our directory of robotic palletizer manufacturers. Each robotic palletizer manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each robotic palletizer business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple robotic palletizer companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

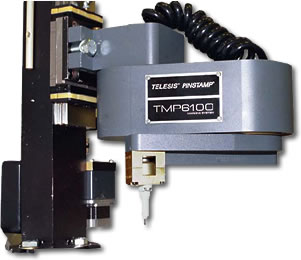

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

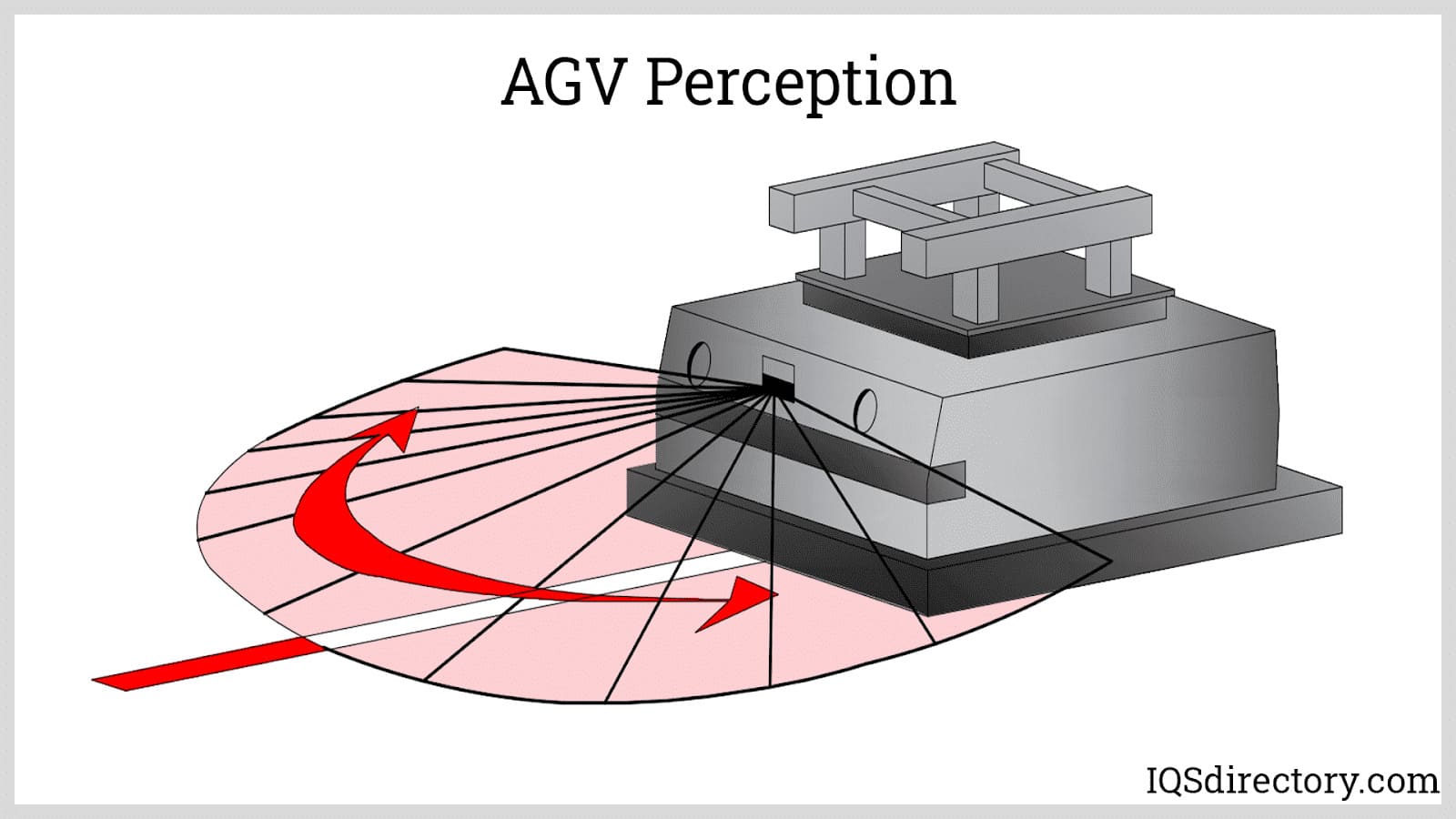

Tape Suppliers AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches